Plasma Reactor

Multi-functional plasma reactors, gasifiers, and cracking chambers

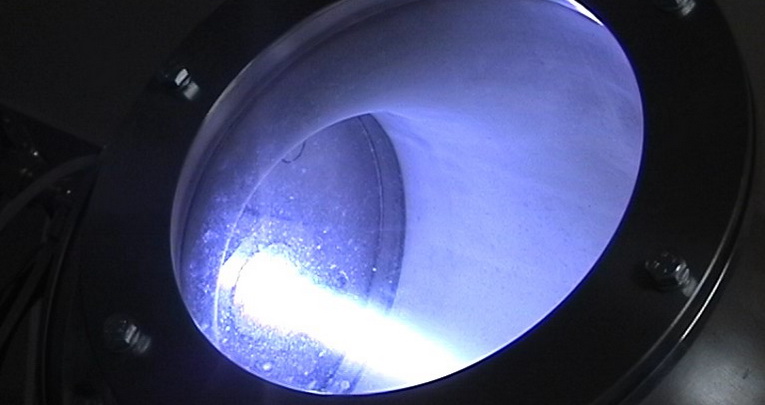

Oenerga PCR plasma reactors are complicated plasma units where reactions with the use of low-temperature plasma take place. Oenerga PCR plasma reactors are designed for sufficient mixing of reagents; for creating conditions for efficient heat and mass transfer at minimal heat losses; for creating conditions for the necessary chemical reactions, including for the purposes of non-ore material melting and waste disposal.

OENERGA PCR PLASMA

The possibility of using Oenerga PCR plasma reactors in special-purpose structures and special configurations for plasma destruction of chemical, biological, and bacteriological weapon components, destruction of chemical production wastes including organ halogen wastes, pesticides past their expiration dates, polychlorinated biphenyls and other persistent organic pollutants, for destruction of medical wastes, various toxic wastes, and reduction of radioactive waste storage volume, expands the opportunities of equipment application significantly.

The Oenerga PCR plasma-chemical reactors use practical inertia- less heating element, the electric arc.

plasma reactors are divided into 3 groups

hazardous

chemical, toxic, biological, bacteriological, medical, and radioactive

standard

gasifiers for standard types of wastes and raw materials MSW, biomass, coal, oil sludges, industrial wastes, etc

chemical

Plasma-chemical reactors for specialized, scientific, and technological applications.

Afterburning and treatment of the effluent gases at different industrial enterprises and plants

The Oenerga PCR multi-functional plasma afterburning and plasma cracking chambers (plasma-chemical reformers) allow for effluent gas treatment at plants and industrial enterprises performing air emissions, with full destruction of resins, dioxins and furans that is achieved by way of long-term regulated impact in the plasma chamber through labyrinth paths of the afterburner at temperatures exceeding 1400°С, and subsequent high-speed cooling of the gas.